Material Copper BS: 1977

Finish: Electro Tinned

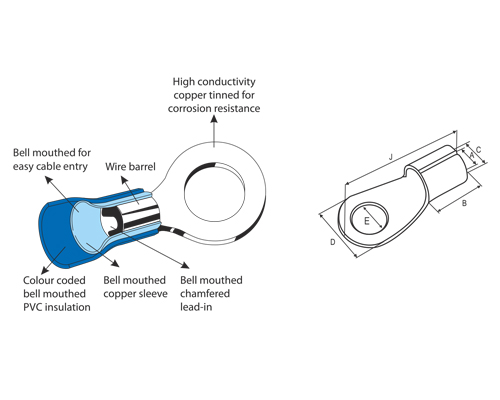

Braco Ring Terminals are designed to offer maximum efficiency under heavy-duty applications. Therefore these terminals are ideal for use in applications which are subject to continuous mechanicals vibrations viz. engines, railways, moving components etc. The terminal barrel is brazed and soft annealed, which means that the terminal can be crimped in either direction.

All the terminals are tin plated to avoid oxidization and to achieve maximum corrosion protection. These terminals can be provided with PVC sleeves for protection against electrical shocks and can also be provided with metal reinforced sleeves to maintain a proper grip on conductor insulation.

Download Brochure

Download Brochure