Copper Crimping Ring Terminals (Non Insulated)

Braco Copper Crimping Ring Terminals are designed to offer maximum efficiency under heavy-duty applications that are subject to continuous Mechanical Vibration ie Engines, Railways, Moving Components etc.

Material: Copper BS: 1977

Finish: Electro Tinned

| Features | Advantages |

|---|---|

| Tin Plated | To avoid oxidization and achieve Maximum corrosion protection |

| Brazed Barrel & Soft Annealed | To give crimping option on either side |

Details coming soon...

Details coming soon...

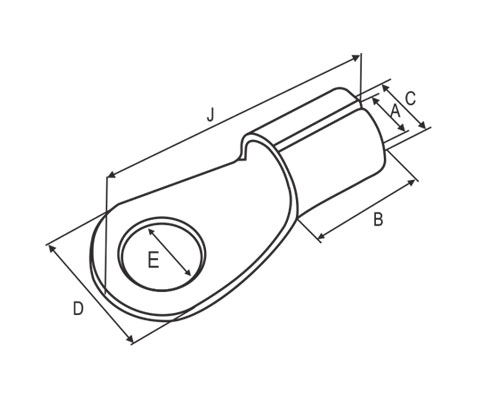

| Size Sq.mm |

Dimensions | Code No |

|||||

|---|---|---|---|---|---|---|---|

| E | A | C | D | B | J | ||

| 10 | 5.2 | 4.3 | 6.3 | 10 | 8 | 20 | R-026 |

| 6.4 | 4.3 | 6.3 | 12 | 8 | 23 | R-120 | |

| 8.2 | 4.3 | 6.3 | 16 | 8 | 27 | R-121 | |

| 8.2 | 4.3 | 6.3 | 18 | 8 | 30 | R-122 | |

| 10.2 | 4.3 | 6.3 | 18 | 8 | 30 | R-027 | |

| 10.2 | 4.3 | 6.3 | 22 | 8 | 34 | R-123 | |

| 12.7 | 4.3 | 6.3 | 22 | 8 | 34 | R-028 | |

| 16 | 6.4 | 5.6 | 8 | 12 | 10 | 26 | R-029 |

| 8.2 | 5.6 | 8 | 16 | 10 | 30 | R-030 | |

| 8.2 | 5.6 | 8 | 18 | 10 | 33 | R-127 | |

| 10.2 | 5.6 | 8 | 18 | 10 | 33 | R-032 | |

| 10.2 | 5.6 | 8 | 22 | 10 | 35 | R-128 | |

| 12.7 | 5.6 | 8 | 22 | 10 | 35 | R-033 | |

| 25 | 6.4 | 7.5 | 11.1 | 12 | 11 | 31 | R-156 |

| 8.2 | 7.5 | 11.1 | 12 | 11 | 31 | R-051 | |

| 8.2 | 7.5 | 11.1 | 16 | 11 | 30 | R-034 | |

| 10.2 | 7.5 | 11.1 | 16 | 11 | 30 | R-035 | |

| 8.2 | 7.5 | 11.1 | 18 | 11 | 34 | R-036 | |

| 10.2 | 7.5 | 11.1 | 18 | 11 | 34 | R-131 | |

| 10.2 | 7.5 | 11.1 | 22 | 11 | 42 | R-132 | |

| 12.7 | 7.5 | 11.1 | 22 | 11 | 42 | R-037 | |

| Size Sq.mm |

Dimensions | Code No |

|||||

|---|---|---|---|---|---|---|---|

| E | A | C | D | B | J | ||

| 35 | 6.4 | 9 | 12.6 | 16 | 12 | 31 | R-133 |

| 8.2 | 9 | 12.6 | 16 | 12 | 31 | R-038 | |

| 8.2 | 9 | 12.6 | 18 | 12 | 36 | R-134 | |

| 10.2 | 9 | 12.6 | 18 | 12 | 36 | R-039 | |

| 10.2 | 9 | 12.6 | 22 | 12 | 42 | R-135 | |

| 12.7 | 9 | 12.6 | 22 | 12 | 42 | R-040 | |

| 50 | 8.2 | 10.5 | 14.1 | 18 | 16 | 43 | R-136 |

| 10.2 | 10.5 | 14.1 | 18 | 16 | 43 | R-041 | |

| 10.2 | 10.5 | 14.1 | 22 | 16 | 43 | R-137 | |

| 10.2 | 10.5 | 14.1 | 24 | 16 | 48 | R-138 | |

| 12.7 | 10.5 | 14.1 | 24 | 16 | 48 | R-042 | |

| 16.2 | 10.5 | 14.1 | 32 | 16 | 54 | R-139 | |

| 70 | 10.2 | 12 | 16 | 22 | 18 | 47 | R-140 |

| 12.7 | 12 | 16 | 22 | 18 | 47 | R-043 | |

| 12.7 | 12 | 16 | 24 | 18 | 48 | R-141 | |

| 16.2 | 12 | 16 | 28 | 20 | 54 | R-142 | |

| 95 | 10.2 | 13.5 | 18.1 | 22 | 20 | 46 | R-143 |

| 10.2 | 13.5 | 18.1 | 24 | 20 | 50 | R-144 | |

| 12.7 | 13.5 | 18.1 | 24 | 20 | 50 | R-044 | |

| 16.2 | 13.5 | 18.1 | 28 | 20 | 58 | R-145 | |

| 120 | 12.7 | 15 | 20.2 | 26 | 22 | 52 | R-146 |

| 16.2 | 15 | 20.2 | 32 | 22 | 64 | R-147 | |

| 20.3 | 15 | 20.2 | 40 | 22 | 72 | R-148 | |

| 150 | 12.7 | 16.5 | 23.7 | 34 | 24 | 66 | R-149 |

| 16.2 | 16.5 | 23.7 | 34 | 24 | 66 | R-045 | |

| 16.2 | 16.5 | 23.7 | 40 | 24 | 74 | R-150 | |

| 20.3 | 16.5 | 23.7 | 40 | 24 | 74 | R-046 | |