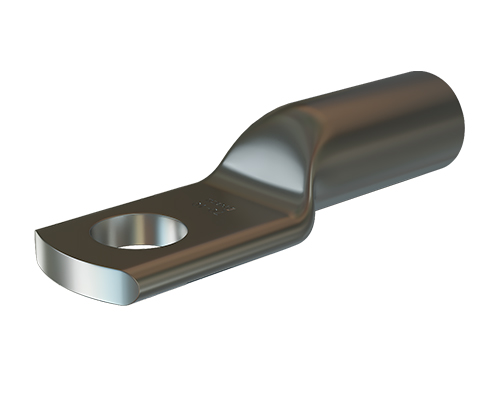

Aluminium Alloy Tubular Bimetallic Terminals

Crafted from aluminum with a purity equal to or greater than 99.5%, Braco Aluminium Alloy Tubular Bi-Metallic Terminals exhibit a maximum conductivity not less than 60% IACS. Specifically designed for highly corrosive environments, these terminals are anti-corrosive, ensuring durability in challenging conditions.

The barrels are kept filled with grease, preventing the oxidization of aluminum. These terminals are versatile, accepting a variety of conductor forms, especially low stranded compacted conductors. Primarily used to terminate on copper bus bars, they address the issue of corrosion in joints when aluminum links terminate on copper or copper-based alloy terminals without suitable plating. Bimetallic terminals provide a reliable and corrosion-resistant solution for such connections. Explore the anti-corrosive reliability of Braco Aluminium Alloy Tubular Bi-Metallic Terminals in diverse applications.

Material: Aluminium IS:5082:1981

Details coming soon...

Details coming soon...

| CABLE Size MM2 |

Dimensions | BRACO CAT NO. | |||||

|---|---|---|---|---|---|---|---|

| E | A | C | D | B | J | ||

| 10 | 6.4 | 4.4 | 7.4 | 11 | 9 | 30 | ATB-1 |

| 8.2 | 4.4 | 7.4 | 13 | 9 | 30 | ATB-2 | |

| 16 | 6.4 | 5.4 | 8.3 | 11 | 13 | 37 | ATB-3 |

| 8.2 | 5.4 | 8.3 | 12 | 13 | 37 | ATB-4 | |

| 25 | 8.2 | 7 | 9.7 | 14 | 16 | 44 | ATB-5 |

| 10.2 | 7 | 9.7 | 17 | 16 | 44 | ATB-6 | |

| 35 | 8.2 | 8 | 10.8 | 15 | 18 | 47 | ATB-7 |

| 10.2 | 8 | 10.8 | 17 | 18 | 47 | ATB-8 | |

| 50 | 8.2 | 9.3 | 13 | 18 | 22 | 54 | ATB-9 |

| 10.2 | 9.3 | 13 | 18 | 22 | 54 | ATB-10 | |

| 70 | 10.2 | 11.1 | 15.4 | 22 | 26 | 60 | ATB-11 |

| 12.7 | 11.1 | 15.4 | 22 | 26 | 60 | ATB-12 | |

| 95 | 10.2 | 13.5 | 17.3 | 25 | 28 | 64 | ATB-13 |

| 12.7 | 13.5 | 17.3 | 25 | 28 | 64 | ATB-14 | |

| 120 | 10.2 | 14.8 | 19.6 | 28 | 32 | 73 | ATB-15 |

| 12.7 | 14.8 | 19.6 | 28 | 32 | 73 | ATB-16 | |

| 150 | 12.7 | 16.6 | 21.4 | 31 | 34 | 79 | ATB-17 |

| 16.2 | 16.6 | 21.4 | 31 | 34 | 79 | ATB-18 | |

| 185 | 12.7 | 18.5 | 24 | 34 | 36 | 84 | ATB-19 |

| 16.2 | 18.5 | 24 | 34 | 36 | 84 | ATB-20 | |

| 240 | 12.7 | 22 | 28 | 40 | 44 | 102 | ATB-22 |

| 16.2 | 22 | 28 | 40 | 44 | 102 | ATB-23 | |

| 300 | 16.2 | 24 | 31 | 45.7 | 47 | 115 | ATB-24 |

| 20.3 | 24 | 31 | 45.7 | 47 | 115 | ATB-25 | |

| 400 | 20.3 | 28 | 36 | 51 | 56 | 130 | ATB-26 |

| 500 | 20.3 | 30.2 | 41 | 58 | 60 | 140 | ATB-27 |

| 630 | 20.3 | 35 | 46 | 66 | 69 | 154 | ATB-28 |

| 800 | - | 39 | 51 | 73 | 77 | 180 | ATB-29 |

| 1000 | - | 43.5 | 57 | 81 | 100 | 220 | ATB-30 |