Copper Crimping Terminals As per Din Standards

Braco Copper Tube Terminals: Reliable Connectivity

Crafted from Electrolytic Copper Tube, Braco Copper Tube Terminals

ensure optimal electrical conductivity and mechanical strength,

resisting vibration and pull-out forces. Versatile for terminating

cables of any size, these terminals shine in critical environments like

electrical switching equipment.

Annealed for optimum ductility, these terminals withstand severe

deformation during compression and palm bending, crucial for

connectors in vibrating applications. The design adheres to DIN

standard 46235, ensuring quality and consistency.

Plated to prevent oxidization, these terminals offer maximum corrosion

protection, enhancing their durability. Choose Braco Copper Tube

Terminals for reliable connectivity in diverse applications.

Material: Copper BS: 1977

Finish: Electro Tinned

Details coming soon...

Details coming soon...

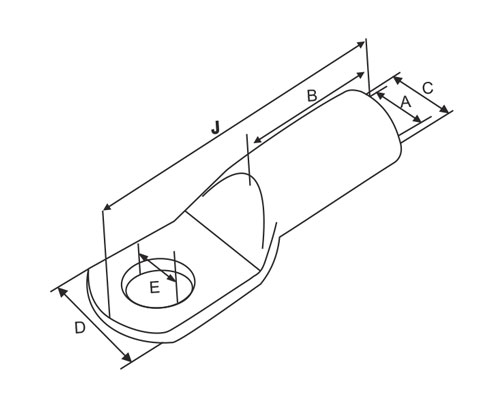

| Size Sq. mm |

Dimensions | BRACO CAT NO. | |||||||

|---|---|---|---|---|---|---|---|---|---|

| E | A | C | B | D | G | H | J | ||

| 6 | 5.3 | 3.8 | 5.5 | 10 | 8.5 | 6.5 | 7.5 | 31 | 6-5 DIN |

| 6.5 | 3.8 | 5.5 | 10 | 8.5 | 7.5 | 8 | 32 | 6-6 DIN | |

| 10 | 6.5 | 4.5 | 6 | 10 | 8.5 | 7.5 | 8 | 35 | 10-6 DIN |

| 8.5 | 4.5 | 6 | 10 | 8.5 | 10 | 10 | 37 | 10-8 DIN | |

| 16 | 6.5 | 5.5 | 8.5 | 20 | 12 | 7.5 | 8 | 43 | 16-6 DIN |

| 8.4 | 5.5 | 8.5 | 20 | 12 | 10 | 10 | 45 | 16-8 DIN | |

| 10.5 | 5.5 | 8.5 | 20 | 17 | 12 | 12 | 49 | 16-10 DIN | |

| 13 | 5.5 | 8.5 | 20 | 19 | 13 | 13 | 50 | 16-12 DIN | |

| 25 | 6.5 | 7 | 10 | 20 | 15 | 7.5 | 8 | 47 | 25-6 DIN |

| 8.4 | 7 | 10 | 20 | 15 | 10 | 10 | 49 | 25-8 DIN | |

| 10.5 | 7 | 10 | 20 | 17 | 12 | 12 | 51 | 25-10 DIN | |

| 13 | 7 | 10 | 20 | 19 | 13 | 13 | 52 | 25-13 DIN | |

| 35 | 8.4 | 8.2 | 12.5 | 20 | 17 | 7.5 | 8 | 50 | 35-8 DIN |

| 10.5 | 8.2 | 12.5 | 20 | 19 | 10 | 10 | 52 | 35-10 DIN | |

| 13 | 8.2 | 12.5 | 20 | 21 | 12 | 12 | 54 | 35-12 DIN | |

| 50 | 8.4 | 10 | 14.5 | 28 | 22 | 10 | 10 | 61 | 50-8 DIN |

| 10.5 | 10 | 14.5 | 28 | 22 | 12 | 12 | 63 | 50-10 DIN | |

| 13 | 10 | 14.5 | 28 | 23 | 13 | 13 | 64 | 50-12 DIN | |

| 17 | 10 | 14.5 | 28 | 28 | 14.5 | 14.5 | 66 | 50-16 DIN | |

| 70 | 10.5 | 11.5 | 16.5 | 28 | 24 | 10 | 10 | 64 | 70-10 DIN |

| 13 | 11.5 | 16.5 | 28 | 24 | 12 | 12 | 66 | 70-12 DIN | |

| 17 | 11.5 | 16.5 | 28 | 32 | 13 | 13 | 67 | 70-16 DIN | |

| 21 | 11.5 | 16.5 | 28 | 32 | 14.5 | 14.5 | 69 | 70-20 DIN | |

| Size Sq. mm |

Dimensions | BRACO CAT NO. | |||||||

|---|---|---|---|---|---|---|---|---|---|

| E | A | C | B | D | G | H | J | ||

| 95 | 10.5 | 13.5 | 19 | 35 | 28 | 12 | 12 | 76 | 95-10 DIN |

| 13 | 13.5 | 19 | 35 | 28 | 12 | 12 | 76 | 95-12 DIN | |

| 17 | 13.5 | 19 | 35 | 32 | 13 | 13 | 80 | 95-16 DIN | |

| 21 | 13.5 | 19 | 35 | 34 | 14.5 | 14.5 | 82 | 95-20 DIN | |

| 120 | 10.5 | 15.5 | 21 | 35 | 32 | 18 | 16 | 83 | 120-10 DIN |

| 13 | 15.5 | 21 | 35 | 32 | 19 | 17 | 84 | 120-12 DIN | |

| 17 | 15.5 | 21 | 35 | 32 | 15 | 19 | 87 | 120-16 DIN | |

| 21 | 15.5 | 21 | 35 | 32 | 16 | 20 | 88 | 120-20 DIN | |

| 150 | 10.5 | 17 | 23.5 | 35 | 34 | 15 | 16 | 92 | 150-10 DIN |

| 13 | 17 | 23.5 | 35 | 34 | 16 | 17 | 93 | 150-12 DIN | |

| 17 | 17 | 23.5 | 35 | 34 | 19 | 20 | 96 | 150-16 DIN | |

| 21 | 17 | 23.5 | 35 | 40 | 16 | 20 | 96 | 150-20 DIN | |

| 185 | 10.5 | 19 | 25.5 | 40 | 37 | 15 | 16 | 96 | 185-10 DIN |

| 13 | 19 | 25.5 | 40 | 37 | 16 | 17 | 97 | 185-12 DIN | |

| 17 | 19 | 25.5 | 40 | 37 | 19 | 20 | 100 | 185-16 DIN | |

| 21 | 19 | 25.5 | 40 | 40 | 19 | 20 | 100 | 185-20 DIN | |

| 240 | 10.5 | 21.5 | 29 | 40 | 42 | 15 | 16 | 106 | 240-10 DIN |

| 13 | 21.5 | 29 | 40 | 42 | 16 | 17 | 107 | 240-12 DIN | |

| 17 | 21.5 | 29 | 40 | 42 | 19 | 20 | 110 | 240-16 DIN | |

| 21 | 21.5 | 29 | 40 | 46 | 21 | 20 | 112 | 240-20 DIN | |

| 300 | 13 | 24.5 | 32 | 50 | 48 | 19 | 22 | 119 | 300-12 DIN |

| 17 | 24.5 | 32 | 50 | 48 | 19 | 22 | 119 | 300-16 DIN | |

| 21 | 24.5 | 32 | 50 | 48 | 21 | 22 | 121 | 300-20 DIN | |

| 400 | 17 | 27.5 | 38.5 | 70 | 55 | 25 | 25 | 140 | 400-16 DIN |

| 21 | 27.5 | 38.5 | 70 | 55 | 25 | 25 | 140 | 400-20 DIN | |

| 500 | 21 | 31 | 42 | 70 | 60 | 25 | 25 | 152 | 500-20 DIN |

| 625 | 21 | 34.5 | 44 | 80 | 60 | 25 | 25 | 160 | 625-20 DIN |